My cutting board is exhausted. After decades of being the workhorse for family meals, celebrations, and holiday dinner preparations, it’s ready to retire. A few cracks are opening up in the rock maple seams. The edges are turning black from too much time drying on a damp drainboard. And the surface, with its thousand tiny cuts, is no longer smooth.

Purchased in Vermont decades ago, the simple 11 by 18 slab of glued-together inch-thick planks has given yeoman service. It was smooth on both sides until I tried to carve out a moat around the rim. That rock maple is pretty tough, but I did finally rout a groove that was, it turned out, too shallow to do any good.

Our collection of cutting boards

Fortunately, there was a new board under the Christmas tree this year. More appropriately called a block than a board this chunky hunk of wood measured 2 ¼ inches thick and weighed in at 18 pounds. Made by the famous John Boos & Company, it’s a serious kitchen tool. Flat on one side, there’s a deep trench around the edge of the other to trap any carving juices. Finger slots cut into the edges make it easy to pick up.

There’s no need to worry that this weighty block will move, slip, or slide. No matter what the task, it’s more than able to support the work and give a solid feeling of professional poise.

Cutting boards are the unsung heroes of the kitchen, the foundation of any meal. Perhaps, like me, you have a favorite and others that are hardly used. A cook can’t function without a board.

Color coded boards used in commercial kitchens

In a commercial kitchen, when a cook comes to work, the first step in setting up is to grab a cutting board. They’re fundamental to the profession.

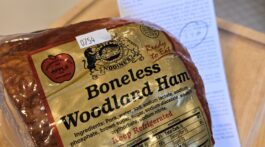

Cutting boards come in an unexpected range of shapes, sizes, and materials. Some have a special purpose like carving, cutting bar fruit, or presenting cheese, but most are general-purpose every-day tools of the trade.

Wood, of course, is the time-honored material. That’s why the’re called cutting boards. Not all are wood though. Various types of composite and plastic materials are used to make products that are more sanitary, easier to clean, and maybe a little more stylish.

Rock maple, the preferred material for generations, is also known as hard maple or sugar maple. It’s the same tree that is tapped to make maple syrup and produces the luxurious wood that makes curly maple furniture and high-end guitars. You can’t beat a maple cutting board for home use.

John Boos & Company has been making cutting boards and blocks in Effingham, IL for more than 125 years. They come rectangular, square, and round, designed for all types of cutting. Rock maple is the most popular, but walnut and cherry woods are also available. Most are boards glued side to side, but there are also end grain blocks that look like crossword puzzles.

In Dorset, VT the J. K. Adams Company has been handcrafting cutting boards since 1944. They have a wide range of styles from old school to one so up-to-date that it has a slot to hold your smartphone while you work. Adams boards can be personalized with initials, logo, or saying. They also offer a wide range of serving boards and bowls.

In Dorset, VT the J. K. Adams Company has been handcrafting cutting boards since 1944. They have a wide range of styles from old school to one so up-to-date that it has a slot to hold your smartphone while you work. Adams boards can be personalized with initials, logo, or saying. They also offer a wide range of serving boards and bowls.

Catskill brand cutting boards are manufactured in Stamford, NY, at the headwaters of the Schoharie Creek and the Delaware river. Made from local and sustainable wood, they have a number of designs in end grain wood as well as traditional styles. Catskill cutting boards are available at the Cook’s Nook in Wilton.

Wood cutting boards are a marvel of engineering and craftsmanship. Some rise to the level of artistry. A quick Google search will turn up lots of hits for cutting boards made with exotic woods, one-of-a-kind designs, and with beautiful wood inlay or patterns.

Wood cutting boards are a marvel of engineering and craftsmanship. Some rise to the level of artistry. A quick Google search will turn up lots of hits for cutting boards made with exotic woods, one-of-a-kind designs, and with beautiful wood inlay or patterns.

Fast-growing bamboo is a great material for cutting boards. The tough wood resists cutting and is easy to clean. Usually laminated for strength, bamboo boards can be thinner and lighter than hardwood boards. One of my favorite foodie gifts is a bamboo cutting board in the shape of Connecticut. Town names are printed on the board. Greenwich is the handle.

Plastic polyethylene cutting boards are popular, particularly in commercial use. They’re recommended by the National Sanitation Foundation for their impervious, easily cleaned surface. Made in colors so you can restrict use, you can use one color for meat, another for fish, and a third for vegetables to keep cross contamination at a minimum. Practical, they lack the beauty and soul of a natural wood board.

Plastic polyethylene cutting boards are popular, particularly in commercial use. They’re recommended by the National Sanitation Foundation for their impervious, easily cleaned surface. Made in colors so you can restrict use, you can use one color for meat, another for fish, and a third for vegetables to keep cross contamination at a minimum. Practical, they lack the beauty and soul of a natural wood board.

Composite cutting boards, usually thinner and lighter than both wood and polyethylene, are made from phenolic resins and wood fibers. They’re attractive, tough, and stylish, but I prefer something thicker.

At home, the new Boos block and a smaller bamboo board are in everyday use. There’s a small bar board for bar fruit and an old one with a handle that sticks out, good for bread. Pig and piano shapes make great presentations. I know have plenty of cutting boards, but I’ve always got my eye out for just one more.

Frank Whitman can be reached at NotBreadAloneFW@gmail.com.

Cutting boards at the Cook’s Nook in Wilton

No Comment